M35+V Spray Forming Powder HSS Tool Steel

Spray forming Powder Metallurgy M35+V high-speed steel increases the content of V element on the basis of M35 to improve its wear resistance. More cost-effective on slow cutting hob.

SPECIFICATION

| SIMILAR STEEL GRADES | ||||||

| National Standard | Manufacturer Standard | |||||

| GB | AISI | DIN | JIS | Erasteel | Bohler | Hitachi |

| W6Mo5Cr4V2Co2+V | M35+V | 1.3243+V | SKH55+V | EM35+V | S705+V | YXM4+V |

|

Chemical composition % |

||||||||||

| C | Si | Mn | P ≤ | S ≤ | Cr | W | Mo | V | Co | etc. |

| 1.05 | 0.30 | 0.30 | 0.025 | 0.01 | 4.20 | 6.20 | 4.95 | 2.45 | 4.70 |

|

|

Characteristics |

|||

| Annealed Hardness HB | Heat Treatment Temperature ℃ | Tampering HardnessHRC | |

| Hardening | Tempering | ||

| 280 | 1190-1210 | 540-600 | 65-67 |

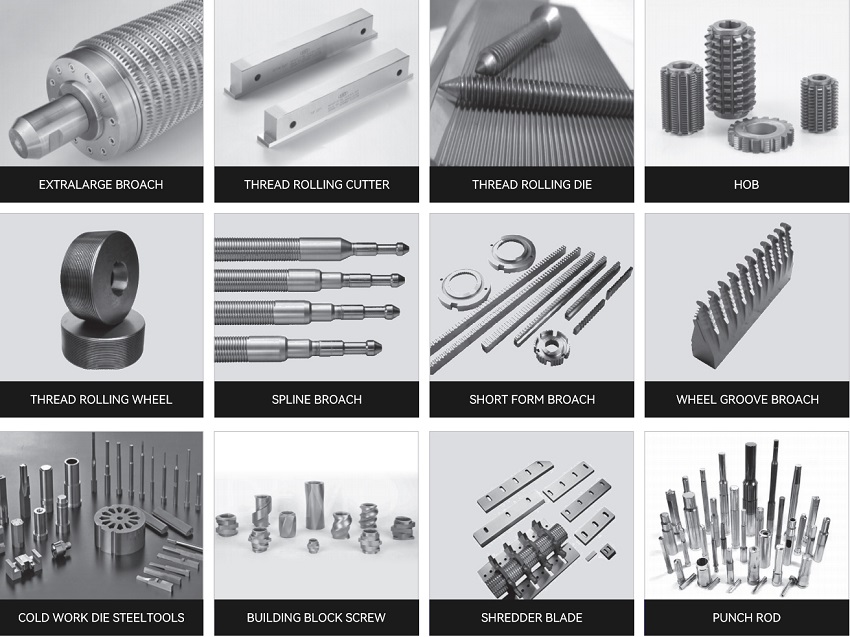

Applications

Broaches, Reamers, Mills Gear Cutting, Shaving, Shaping Tools, Twist Drills, Taps Special Cutting Tools, Blades for Sawing Machines, Holemaking, Threading cutters, Milling cutters, Tooth cutting cutters, Broaching cutters, Sawing cutters - machine saw blades, band saw edges, Stamping dies - punching rods, fine blanking dies

Supply Form

|

|