The Product Application

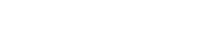

Cutters —— The main applications of HSS in cutting tools are drills, taps, milling cutters, hobs, broaches, etc. The material used to manufacture the tool must have high high temperature hardness and wear resistance, the necessary flexural strength, impact toughness and chemical inertness, good workmanship (cutting, forging and heat treatment, etc.) and be resistant to deformation. Contact Us → |

|

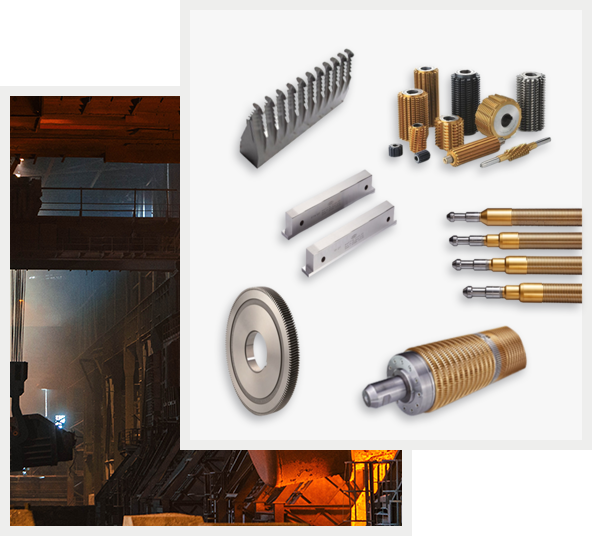

| Dies — In the dies application is divided into cold work steel, hot woold steel.Cold work steel mostly work at room temperature, the plastic deformation resistance of the material is large, the working stress of the mould is large, the working conditions are harsh, integrated this kind of mould performance generally requires high hardness and wear resistance, sufficient strength, appropriate toughness. Hot steel for a long time in high temperature and high pressure conditions, therefore, require mold materials with high strength, hardness and thermal stability, especially should be high thermal strength, thermal fatigue, toughness and wear resistance. Contact Us → |

Knives —— When material is to be separated, slotted, granulated or chipped, the tools that can be used are knives. Knives can come in a variety of forms, from flat tools with a very sharp cutting edge, to round tools with several cutting edges. They can be used for a variety of materials and applications including: cutting wood, textiles, paper, plastic, rubber, metals. In the field of cutting inserts, what is required is good dimensional stability, hardness and wear resistance of the cutting tool edges. Contact Us → |

|

| Others —— The twin-screw element is the most widely used element in today's co-rotating twin-screw compound extruders. Extrusion process can be seen, the screw is in high temperature, a certain corrosion, strong wear, high torque work, therefore, the screw must be high temperature, high temperature, no deformation; wear resistance, long life; corrosion resistance, high strength, can withstand high torque, high speed;, with good cutting performance. Small residual stress after heat treatment, small thermal deformation, etc. Contact Us → |