ESR electroslag remelting method

Electroslag remelting furnace is a device that uses the heat energy generated by electric current flowing through high resistance slag to remelt metals. Electroslag remelting is generally carried out under atmospheric pressure, and vacuum units can also be configured for vacuum refining as required.

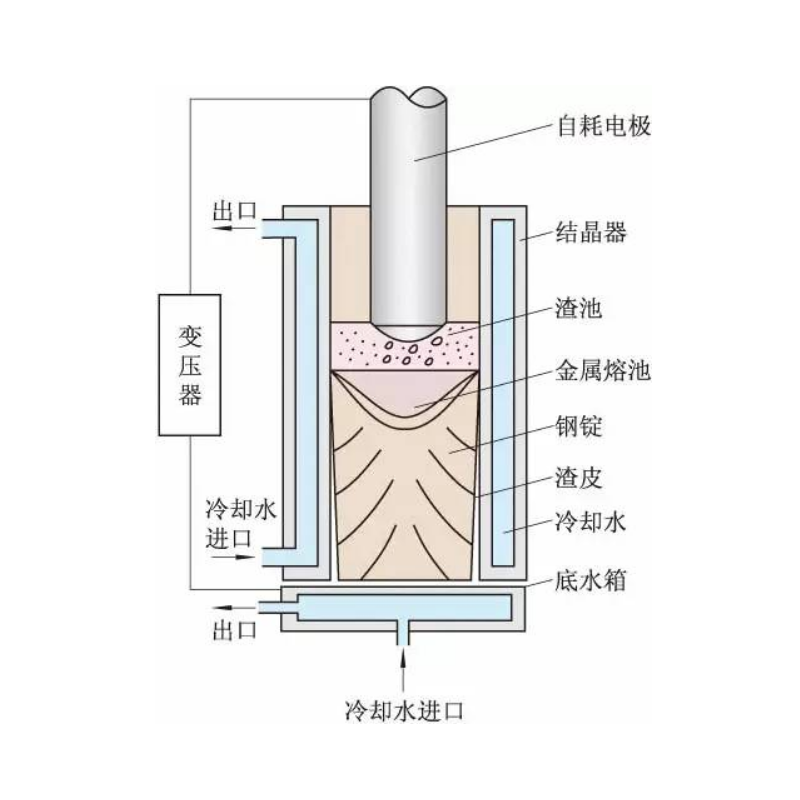

From the heating principle, electroslag remelting furnace is a resistance melting furnace. The electroslag remelting process involves immersing the lower end of the electrode in molten slag. When AC current passes through a high resistance slag pool, it generates a large amount of heat, which melts the electrode ends immersed in the molten slag. The molten metal droplets pass through the slag pool and drop into the metal molten pool, and then are cooled by a water cooled crystallizer and condensed into ingots. In this process, the metal droplets fully contact with high-temperature and high-alkalinity slag, resulting in a strong metallurgical chemical reaction, making the metal refined. The key technology of electroslag remelting furnace is the slag system. In electroslag remelting furnaces, the main functions of slag are as follows: heat source, protection, molding, and metallurgical chemistry. The chemical composition of slag has a significant impact on the quality and technical and economic indicators of electroslag smelting products.

The characteristics of molten slag are: (1) It has a high resistivity and can generate sufficient heat during the melting process to ensure the melting, heating, and purification of the metal. (2) It has a certain alkalinity, so its deoxidation and desulfurization effects are good. (3) It does not contain unstable oxides such as MnO, FeO, etc. (4) It has good fluidity to ensure sufficient convective heat exchange and liquid physical and chemical reactions at high temperatures. (5) It has a lower melting point, generally 150-250 ℃ lower than the melting point of the molten metal, which makes the spindle well formed. (6) It has a high boiling point so as not to cause a large amount of volatilization at high temperatures.